Approximately 56 billion coffee pods are consumed each year which end up in the landfill and can take up to 500 years to decompose, leaving behind contamination and microplastics. Recyclable pods, meanwhile, often include non-recyclable plastic and aluminum – making them less likely to be recycled properly or recycled at all.

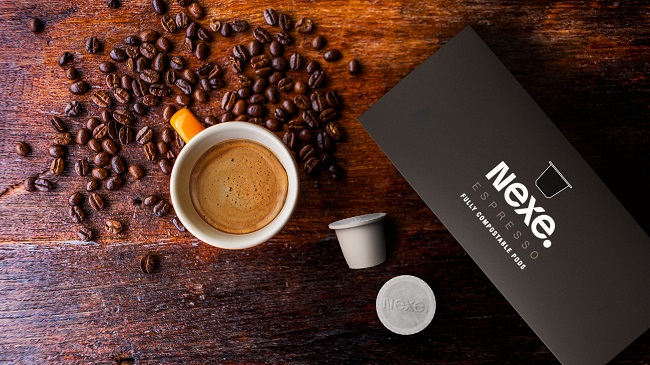

Entire Vancouver, B.C.-based NEXE Innovations Inc. Known for its plant-based materials manufacturing, NEXE recently launched compostable, espresso pods in the U.S. and Canada. This is the first NEXE-branded coffee product that the company is introducing into the single-serve coffee pod market, currently valued at more than USD$25 billion annually.

SEE Change sat down with Ash Guglani, President of NEXE Innovations Inc., to learn more about the innovation, its unique properties and the efforts that brought it to market (despite a hiccup or two).

Tell us about NEXE and what inspired the espresso pod launch

NEXE Innovations is focused on developing sustainable, plant-based, advanced materials, with a focus on compostable, single-use products. The company’s flagship product is its patented, fully compostable, plant-based, single-serve coffee pod: The NEXE Pod, which can be used in leading single-serve coffee machines.

Every year, more than 59 billion single-use coffee pods are consumed, with 56 billion of those being discarded in landfills around the world where they can take 500 – 10,000 years to decompose, leaving behind contamination and microplastics when they do. While recyclable coffee pods may seem like a simple solution, these too find their way to landfills all too often.

This is because in order to be properly recycled, each of the components must be separated and cleaned before being disposed of – negating much of the convenience that the consumer was seeking from the pods in the first place. And even when this is done, it still might not be enough to stop these pods from ending up in landfills. Many areas of the world don’t have the proper infrastructure or technology to sort and recycle the materials. Less than 9% of plastic is recycled worldwide.

Conversely, our entire pod is compostable so there is no need to separate the lid, cup, or coffee, making it easy to live zero-waste.

Tell us about what makes your espresso pod unique

The NEXE Espresso Pod is unique in that it is fully compostable but also maintains the coffee’s freshness and flavour just as well as a traditional coffee pod. Its unique casing gives it the strength to remain intact in the intensive brewing process while also holding a large amount of coffee.

The pods break down in as little as 35 days in industrial composting facilities, which is similar to the time it takes an apple core to decompose. The product is zero-waste, leaving behind no harmful byproducts when composted and no effect on the taste of the coffee.

What has been your measurable impact so far?

Earlier this year, we made the decision to do our product design and manufacturing domestically, particularly after witnessing the supply chain disruptions experienced by many food manufacturers throughout the pandemic. And we also saw that we could reduce our impact on the environment significantly by reducing the amount of shipping that automatically comes with outsourcing manufacturing.

Both of our product lines are manufactured in British Columbia using sustainable and environmentally friendly processes such as 3D printing and compostable materials for prototyping. This is in contrast to the traditional method for prototyping which involves manufacturing stainless steel moulds for each iteration. This produces a lot of waste as each mould is thrown out and produces a significant amount of carbon emissions. 3D printing however uses BLA or poly-lactic acid for printing, which is compostable. This process reduces time, waste, and emissions.

What have been the greatest challenges bringing it to market?

When we first started this project, the concept of a compostable coffee pod was a no-brainer, and we thought that it would be simple to develop. Turns out, we were very, very wrong. Creating a material that can withstand the intense heat and pressure of a coffee machine, without impacting flavor or freshness, while also being thin enough to allow for adequate product inside was very difficult. Getting the pod just right took over six years of research and development, and we finally have a fantastic product that both we and our customers are pleased with.

Any lessons learned (so far) about running a social venture?

We have learned that people and planet are not separate but are in fact one and the same. We’ve learned that one cannot be without the other and that furthers our commitment to learning what is needed to support the planet and innovating to support the needs of consumers. We’ve learned that when it comes to the Earth, compromise is not an option and our latest product release reflects our understanding of that.